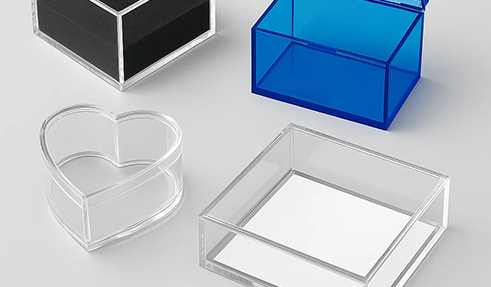

How Thick Should Acrylic Be for a Display Case?

December 23, 2025

Read:105

Source: Dongguan XingfenglinAcrylic Products Co., Ltd

In this guide, we’ll break down how acrylic sheet thickness is measured (and why tolerances matter), what to consider when choosing thickness for an acrylic display case, the most common thickness options and where they work best, and how laser cutting vs. CNC changes the thickness decision.

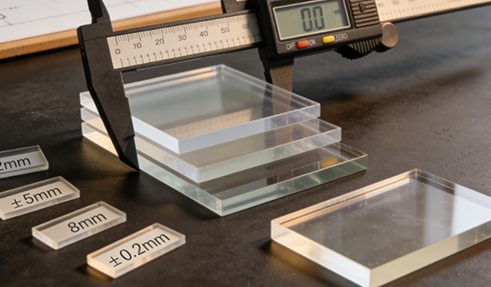

Acrylic Sheet Thickness Explained: How to Read Specs and Tolerances

1.How Thickness Tolerance Affects Fit and Hardware

Acrylic sheets aren’t perfectly uniform, and those “tiny” thickness differences can become surprisingly noticeable once the case is assembled. When you’re aiming for tight seams, even door gaps, or a satisfying magnetic close, tolerance is often what separates a case that feels precise from one that feels slightly off. Just a small change in thickness can nudge panels out of alignment, widen or tighten door clearances, and shift magnet contact points—so the door might snap shut cleanly in one spot but rub or feel misaligned in another.

2.Nominal vs. Actual Thickness—How to Check Before You Build

What to check | Why it matters | Quick tip |

Nominal (labeled) thickness | What your design is based on | Confirm what thickness the supplier lists (e.g., 3mm, 5mm) before quoting or drawing |

Supplier tolerance range | Tells you how much the sheet can vary | Ask for the tolerance spec (e.g., ±0.1mm / ±0.2mm) before finalizing tight fits |

Actual thickness (measured) | The real number your parts must fit | Use calipers and measure multiple spots on the sheet, not just one corner |

Critical clearance areas (slots, doors, magnets) | Small differences can cause rubbing, gaps, or misalignment | Leave a small buffer for slot-fit parts and magnetic doors—avoid “zero clearance” designs |

Consistency across batches | Different batches may behave differently | If you reorder later, re-check thickness—don’t assume it matches the last batch |

Factors to Consider When Choosing Acrylic Display Case Thickness

1.Case Size and Span

Thickness is what keeps an acrylic display case box from feeling flimsy. As the largest panel gets longer—usually the top or the longest side—it’s more likely to bow and can feel slightly “springy” to the touch. Thin acrylic may look fine at first, but over time a long span can start to show subtle waviness, so larger cases typically need thicker sheets or a more supportive structure to stay crisp.

2.Load-Bearing Needs

It’s not just the walls that matter—it’s whatever is carrying the weight inside the acrylic display case. If the base is holding a heavier item, or you’re adding shelves/tiers, stiffness becomes the priority. Thinner bases can slowly sag and shelves can dip under load, which is why the parts that actually support weight often need to be thicker (or reinforced) than the side panels.

3.Doors and Openings

Once you add a door, small alignment issues become much easier to notice on an acrylic display case. Magnetic doors and hinged doors depend on consistent spacing and a stable mounting surface; if a panel flexes, gaps shift and the close can feel uneven. Using thicker acrylic helps the door stay flatter, keeps margins more consistent, and gives magnets or hinges a sturdier anchor—so everything feels smoother and more “finished.”

4.Shipping, Handling, and Stacking

If the acrylic display case will be shipped, moved, or stacked, thickness starts working as protection too. Thicker acrylic handles corner stress, compression, and minor impacts better during transit. And when cases are stacked, pressure concentrates at contact points—so extra thickness, or added reinforcement, reduces the chance of warping, stress marks, or cracking over time.

5.Visual Look and Feel

Thickness also changes the overall presence of a large acrylic display case. Thicker panels tend to look and feel more premium—steadier on the shelf, more rigid in the hand, and visually “substantial.” The tradeoff is optical: thicker edges can create stronger refraction and reflections under certain lighting, so if you’re after a clean, minimal look, it’s worth considering thickness and lighting together.

Common Acrylic Thicknesses and Applications for a Display Acrylic Case

Acrylic Display Case Thickness | Best For | Typical Use Cases |

2mm / 3mm | Small, lightweight, dust protection | Small collectibles, mini figures, simple covers, light-duty display boxes |

4mm / 5mm | Mid-size cases, better rigidity, more premium feel | Standard display cases, sneaker/figure cases, stackable units, cases with simple doors |

6mm / 8mm+ | Large cases, long spans, higher load/anti-bending | Large acrylic display boxes, long panels, heavier items, load-bearing bases/shelves, premium builds |

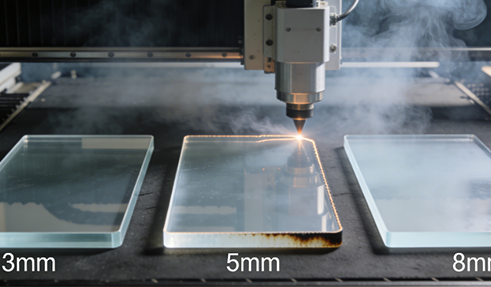

Laser Cutting Acrylic Display Case Boxes: Picking the Right Sheet Thickness

1.Typical Thickness Range for Laser Cutting

Laser cutting works best when it can slice through acrylic cleanly without overheating the sheet. The “easy” thickness range isn’t one-size-fits-all—it depends on laser power, lens setup, air assist, focus accuracy, and how consistent the shop’s settings are from sheet to sheet. Thin material usually cuts fast and leaves a smooth edge because heat doesn’t have time to spread. As the sheet gets thicker, speeds slow down and the margin for error shrinks, which is why—especially if you’re producing an acrylic display case in batches—it’s smarter to choose a thickness your fabricator can repeat reliably, not just something that worked once on a perfect test.

2.What Happens When You Laser-Cut Thick Acrylic

With thicker acrylic, heat stays in the cut zone longer, so edge quality becomes harder to keep “showroom clean.” You may see a faint warm tint, light melt texture, or more noticeable taper because the beam behaves differently through the full depth of the sheet. Heat can also leave internal stress that isn’t obvious at first, but later shows up as hairline cracking around sharp inside corners, small holes, or tight slots. Two simple design habits help a lot: use small inside radii instead of sharp corners, and keep delicate features a bit away from edges where stress concentrates.

3.Precision and Assembly: Leave Room for Kerf

Kerf is tiny, but it decides whether parts assemble smoothly or fight you. In tab-and-slot or friction-fit designs, a “perfect” CAD slot can end up too tight after cutting—especially when sheet thickness varies slightly across a batch. A better approach is to design in a little clearance, then dial it in with a quick test cut using the same acrylic and the same machine settings. For an acrylic display case with doors, magnets, or interlocking panels, aiming for a controlled, comfortable fit (instead of forcing a press-fit) also helps prevent whitening, stress lines, and cracks over time.

4.When CNC Is the Better Choice

CNC is often the better choice when you’re working with thicker sheets, tighter tolerances, or parts that need to work as well as they look. It’s well-suited for pockets, rebates, clean slot geometry, countersunk holes, and structural components—and it avoids many of the heat-related side effects that can show up in thick laser cutting.

At Symphony Acrylic, our CNC machining accuracy typically reaches ±0.05 mm to ±0.1 mm, which helps keep fit and alignment consistent from part to part. That precision matters most in load-bearing panels, hardware mounting areas, and premium acrylic display case boxes where clean assembly, flush edges, and smooth door operation are part of the expected finish. CNC may take longer per piece, but the payoff is usually a cleaner build and more dependable results.

Conclusion

Choosing the right thickness is really about balancing span, load, hardware, and real-world handling. For smaller cases, thinner sheets may be enough; as size, weight, doors, and shipping demands increase, thicker acrylic—or a smarter structure—quickly becomes worth it. And when precision features or thicker material are involved, CNC can deliver more predictable fit and finish. If you’re planning a custom build, Symphony Acrylic can help you select the right thickness and fabrication method based on your dimensions and use case—so your case looks sharp, assembles cleanly, and stays stable over time.

Table of Contents