Why Are Acrylic Display Cases So Expensive?

December 17, 2025

Read:145

Source: Dongguan XingfenglinAcrylic Products Co., Ltd

If you’ve ever shopped for an acrylic display case and felt a bit of sticker shock, you’re not alone. At first glance, it can look like “just a clear box”—but the price reflects far more than the material itself. From the quality of the acrylic sheet and the precision of CNC cutting, to finishing, bonding, inspection, customization, and even shipping protection, every step affects how clear, square, and durable the final case will be.

In this article, we’ll break down the real cost drivers behind an acrylic display case—so you know exactly what you’re paying for and can choose the right one with confidence.

The Material: Acrylic

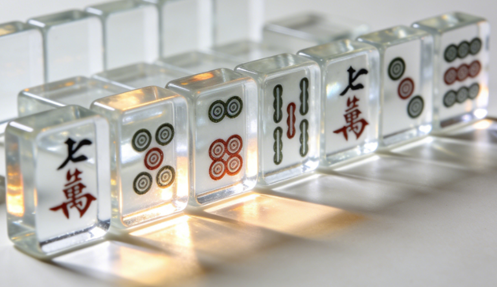

Acrylic (PMMA) isn’t the “cheap plastic” people often assume it is. The acrylic used in premium display cases is chosen for clearer optics and longer-lasting performance—higher-grade sheets look less cloudy, distort the view less, and keep collectibles looking sharp from every angle.

It’s also typically more consistent in thickness, which makes it much easier to achieve tight seams, clean corners, and a case that sits perfectly square. Add better UV stability (so it’s less likely to yellow over time) and strong impact resistance compared with glass at similar thickness, and the price starts to make sense: that “museum-quality” look begins with the material, and better sheet stock simply costs more.

Acrylic Display Case Box Production Process

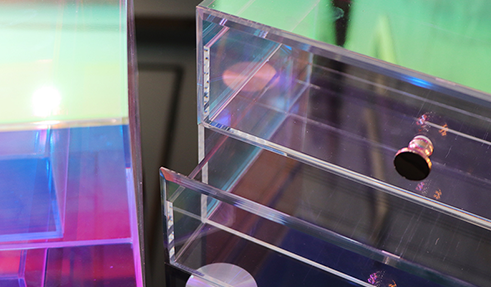

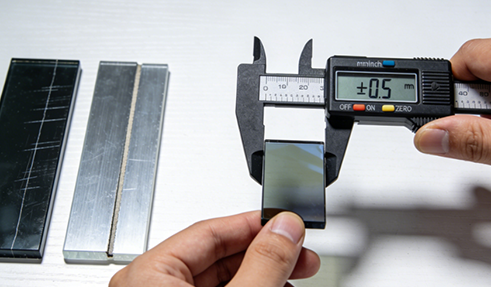

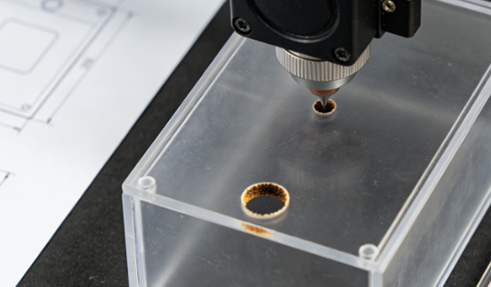

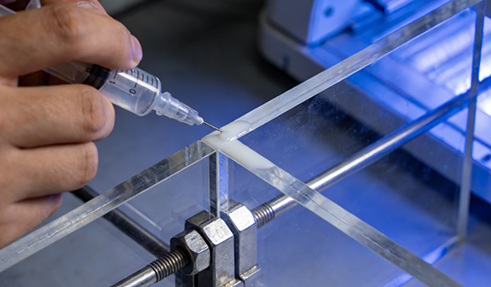

Acrylic display case box rarely come out of a mold in one quick cycle. Most are fabricated from flat sheets, which means every box is the result of several precise, hands-on steps—and that’s where a lot of the cost lives. The work typically begins with laser or CNC cutting to lock in dimensions; on our CNC line, machining accuracy can reach ±0.05 mm to ±0.1 mm, helping panels align neatly and keeping corners crisp and square. After cutting, edges are polished (and in some cases flame-finished) to achieve that clean, glass-like look. If the design calls for wrapped edges or shaped details, the acrylic must be heat-formed with careful control. The final assembly is done with acrylic cement, a process that looks simple but is extremely technique-dependent—small errors can show up immediately as haze, bubbles, stress marks, or seams that don’t match.

To keep results consistent, our custom workflow follows a clear sequence: we start by confirming the design and specs, then move into cutting and surface/edge finishing based on the approved drawing. Next comes any required machining or optional branding details, followed by heat forming when the structure needs it. Once assembled, each piece is checked for fit and appearance, then cleaned and packed with protection so it arrives clear, tight, and ready to display.

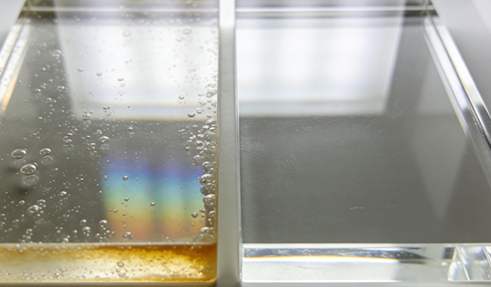

Quality Control for Clear Acrylic Display Cases

Acrylic may look simple, but it’s one of the least forgiving materials to finish well. With a clear acrylic display case, the same clarity that makes your collectibles pop also makes flaws impossible to hide—fine scratches, tiny edge chips, a bit of glue haze, or corners that are even slightly out of square can stand out immediately, especially under bright display lighting. That’s why a premium case isn’t truly “done” the moment it’s assembled; it has to be inspected carefully, and anything that doesn’t meet the standard gets corrected before it leaves the shop.

At Symphony Acrylic, we build that mindset into our process. Every clear acrylic display case is checked before shipment against the confirmed specifications: we assess the sheet condition and overall appearance, verify key dimensions, review surface and edge finishing, and make sure the structure feels stable and precise. We also treat packaging as part of quality control—because even a perfect case can arrive imperfect if it isn’t protected properly. The goal is straightforward: it should arrive clear, clean, and ready to display the moment you open the box.

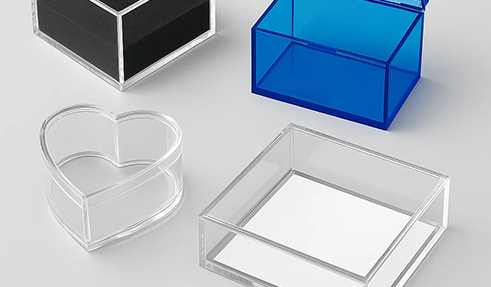

Customization Options for Acrylic Cases for Display

Customization is often the biggest reason an acrylic case for display costs more than you’d expect. Once you go beyond a standard size, it stops being an off-the-shelf item and becomes a build-to-spec piece made around your collectible and how you want it presented. That can mean tighter tolerances, a preferred opening style, cleaner seam placement, subtle branding, or practical details like cutouts and alignment features—each adding design work, setup time, and more careful fabrication. At Symphony Acrylic, we usually start from your drawing or a physical sample, then match the project with the right processes—precision machining for a clean fit, optional UV/silk-screen logo printing, and forming when shaped edges are needed—so the final case feels purpose-built and polished, not simply “close enough.”

Transportation and Handling

Even when raw acrylic isn’t the biggest cost, getting a finished case to your door often is. An acrylic display case box is lighter than glass, but it’s still large, rigid, and easy to scratch—so it can’t be shipped like an ordinary carton. To arrive looking “new,” it has to be packed like a surface-finish product, with enough protection to keep edges, corners, and panels spotless through sorting and transit.

Collectors also highlight a practical issue that pushes freight costs up: these cases don’t fold or compress, so they take up a lot of space on a truck. In one Reddit thread, a commenter noted they “take up a lot of cubic meters” and that “shipping them is expensive”—and that space cost inevitably shows up in the final price.

https://www.reddit.com/r/PokeInvesting/comments/10nfxu1/why_are_acrylic_boxes_so_expensives_it_just/

So part of what you’re paying for includes:

Protective film, foam, and corner guards to prevent scratches and edge damage

Dimensional-weight / oversize charges (carriers often bill by space, not just weight)

Higher transit risk and the built-in cost of replacements/returns when damage happens

Acrylic Display Cases Environmental Considerations

Acrylic isn’t automatically “eco-friendly,” and it’s worth being honest about that. Where a higher-quality acrylic display case box can make a more convincing argument is in how long it lasts: when the case stays clear, stays square, and doesn’t need replacing every year, you end up producing less waste over time. That durability usually comes from smarter material and build choices—UV-stable sheets that resist yellowing, thicker panels and cleaner bonding that help prevent cracking or warping, and designs that let you replace a door or panel if it gets damaged instead of scrapping the entire case. It’s not a perfect sustainability story, but “buy once, use longer” is often the most practical way to reduce impact.

The Acrylic Display Case Box Value of Durability

A well-made clear acrylic display case box is less about decoration and more about reliable protection. Acrylic generally handles everyday bumps better than glass at similar thickness, and when the structure is built with the right thickness and tight, consistent seams, it stays rigid and keeps its shape over time. In real-world use, that strength pays off in simple ways: less dust reaching your collectible, fewer scuffs from handling, and a cleaner, more consistent presentation year after year—especially when the material and finishing are chosen to age well under light. And when you’re protecting something valuable, the case often feels less like an optional add-on and more like a small, sensible form of insurance.

How to Choose the Right Acrylic Display Case

When choosing an acrylic display case, start with three basics: fit, clarity, and long-term stability. Leave a little breathing room inside so your item isn’t brushing the walls, then match the panel thickness to the size of the case—smaller displays can stay sleek, while larger cases usually need thicker acrylic to stay rigid and square. Next, look for the details that separate “okay” from “premium”: well-polished edges, seams that stay clear with minimal haze, and doors that sit flush and feel smooth if you’ll be opening them often. If the case will be near sunlight or strong display lighting, UV-stable material is a smart upgrade to help it stay clear over time. And finally, don’t overlook packaging—shipping is where most scratches and corner damage happen.

If you’re going custom, Symphony Acrylic can work from your drawing or a physical sample and help you fine-tune the sizing, structure, and finishing choices, so the final case feels purpose-built for your display—not just “close enough.”

Conclusion

In the end, acrylic display cases are expensive for the same reason premium collectibles deserve one: the details matter. Higher-grade acrylic, precise fabrication, strict quality control, thoughtful customization, and careful packaging all add cost—but they also add clarity, stability, and long-term protection. If you’re investing in something you want to keep pristine and display proudly, a well-made case isn’t just an accessory—it’s part of the protection plan. And if you need something tailored to your exact item, Symphony Acrylic can work from your drawing or sample to help you build a case that fits, looks right, and arrives display-ready.

Table of Contents