How To Make An Acrylic Display Case

December 9, 2025

Read:199

Source: Dongguan XingfenglinAcrylic Products Co., Ltd

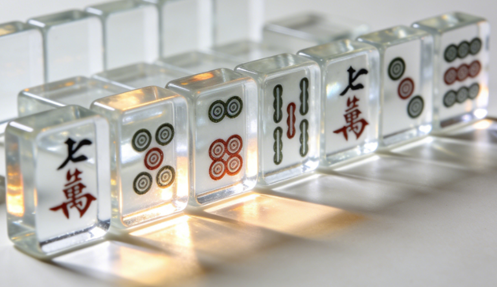

If you’ve ever wished your favorite figure, model, or collectible looked more like it was in a store display than just sitting on a shelf, making your own acrylic display case is a great solution. It keeps dust off, adds a clean modern look, and can be sized perfectly to whatever you want to show.

In this guide, we’ll walk through the whole process step by step—from choosing materials and planning the size, to cutting, sanding, glue-up, and final finishing. Even if you’re new to working with acrylic, you can follow along and build a simple, neat case at home with a few basic tools.

Materials for Your Acrylic Display Case

Before you start building your acrylic display case, it’s a good idea to gather all the basic materials and tools in advance. You don’t need every optional item, but this checklist will help you organize the project and avoid extra trips in the middle of the build.

Acrylic & Structural Materials

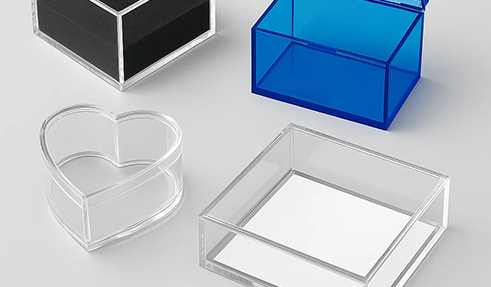

The main body of the acrylic display case is made from acrylic sheets (also known as plexiglass or PMMA). For smaller cases, 2–4 mm thick sheets are usually sufficient; for taller or wider designs, 5–8 mm helps keep the panels stiff and stable. Clear acrylic is the classic choice, while black or colored panels work nicely for the base or back if you want more contrast and a stronger backdrop for your collectibles.

If you don’t want an acrylic base, you can use wood, MDF, or PVC foam board instead. Adding a layer of felt or a non-slip mat on top protects the items and helps keep everything from sliding around.

Adhesives & Fasteners

To bond the panels, acrylic cement or acrylic glue is the most reliable option, especially a thin, solvent-based type that wicks into the joints and creates strong, nearly invisible seams. Using a syringe or applicator bottle gives you better control so the glue stays right along the edge.

If solvent cement isn’t your preference, you can switch to clear epoxy or a more mechanical approach with small screws and metal or plastic brackets. Corner brackets or L-shaped connectors are useful when you want a structure that can be adjusted or taken apart more easily.

Tools

Accurate measurements are key to a neat result, so prepare a tape measure or steel ruler along with a square or right-angle ruler to keep corners at 90°. Mark all cut lines clearly with a pencil or marker before you start cutting.

Choose a cutting method that matches the tools you already have: an acrylic scoring knife for thin sheets, a table saw or circular saw with a fine-tooth blade for plastics on thicker panels, or a laser cutter if you want very clean, precise edges. You’ll also need clamps, corner clamps, or masking tape to hold parts together while the adhesive sets, plus soft or microfiber cloths to wipe away dust and fingerprints safely.

Edge Finishing & Polishing

Prepare several grits of sandpaper, such as 240, 400, 800, 1000, and 1500. Start with a coarser grit and move up to finer ones so the cut edges gradually become smooth and even. A sanding block, or sandpaper wrapped around a flat piece of wood, helps you keep the edges straight and square as you work.

If you want the edges to look clearer and more refined, you can finish them with an acrylic polishing compound. More advanced builders sometimes use a flame polishing tool, but it should always be tested on scrap first—too much heat in one spot can easily warp or scorch the acrylic.

Cleaning & Protection

Once the case is assembled and the adhesive has fully cured, clean the panels with mild soapy water or an acrylic-safe cleaner. Use a microfiber cloth so you don’t scratch the surface, and stay away from ammonia-based products that can damage acrylic over time.

To protect the surface your case sits on, and to keep it stable, add rubber feet or small protective pads under the base. If your design includes a removable cover sitting on a base, thin strips of silicone or foam tape at the contact points can reduce noise, improve grip, and help cut down on fine dust sneaking in.

Safety Gear

Even for a simple acrylic display case project, basic safety gear matters. Wear safety glasses whenever you cut, drill, or sand to shield your eyes from chips and dust. A dust mask is helpful while sanding or cutting acrylic, and gloves are useful when working with solvent-based cements or other adhesives, protecting your skin and making cleanup easier.

Step 1: Plan and Cut Your Acrylic Display Case Box Pieces

In this step, you’ll decide how big your acrylic display case box should be, turn that into a simple drawing, calculate each panel size, and then cut the acrylic. The goal is very practical: when you start cutting, you already know exactly what to cut and why.

1.Decide the Size and Layout

Start by focusing on what you’re actually going to display and where the case will live.

Gather what you want to display.

Put the figure, model, LEGO set, or jewelry together the way you’d like it to be shown (single item, group, in a pose, on a small stand, etc.).

Measure the item.

Use a ruler or tape measure to note the length, width, and height of the tallest/widest part.

Add breathing room.

Don’t make the case exactly the same size as your item. For most projects:

Add at least 2–3 cm on each side and on top.

This extra space makes the display look less cramped and gives room for your hand, bases, or a small riser.

Check the placement location.

Decide where the acrylic display case box will sit:

Desk, shelf, TV stand, inside a cabinet, etc.

Measure that space so you don’t accidentally make a case that’s too tall or too deep.

Choose the structure style.

Decide between:

A separate base (wood or acrylic) with a removable acrylic cover, or

A fully enclosed box with a fixed base (more sealed, less flexible).

2.Draw a Simple Plan

Now turn those numbers into a clear, simple drawing. This doesn’t have to be fancy; it just needs to be useful.

Sketch the box from the front and from the top.

Draw a rectangle for the front view and one for the top view.

Mark the internal length, width, and height.

List the panels you need.

For a basic acrylic display case box with a separate base, you’ll usually have:

1 × top panel

2 × side panels

1 × front panel

1 × back panel

1 × base (optional, wood or acrylic)

Decide how panels overlap.

This part is important for getting sizes right:

Option A: Front and back between the sides

Option B: Sides between the front and back

Pick one method and stick to it. Mark this clearly on your sketch so you remember how everything lines up.

Label everything.

On your drawing, write labels like “Top”, “Side (left)”, “Side (right)”, “Front”, “Back”, “Base”.

This becomes your cut list and makes the next step much easier.

If you’re unsure, you can even cut a quick mock-up from cardboard first to check proportions and layout.

3.Calculate Panel Sizes

With your internal dimensions and overlap style decided, you can now work out the exact size of each acrylic panel.

Let’s define:

Internal width: W

Internal depth: D

Internal height: H

Acrylic thickness: T

If you chose the common layout “sides overlap the front and back”, then:

Front & back panels: W × H

Side panels: D × H

Top panel: W × D

Base (if acrylic): W × D (or slightly larger if you want a little lip)

What you should actually do here:

Take your internal W, D, H from Step 1.1.

Write down the size of each panel next to its name on your sketch.

Check that all panels fit together logically with the thickness you picked.

Go through the list once more and confirm:

“If I glue these edges together, will I really get the internal size I want?”

Spending a few minutes here can easily save you from recutting or wasting a whole sheet of acrylic.

4.Cut the Acrylic

Once you’re happy with the plan and panel sizes, you can start cutting. Choose the method that matches your tools and acrylic thickness.

Before you cut, do this for all methods:

Leave the protective film on both sides to avoid scratches.

Mark all cut lines clearly with a fine marker or pencil.

Support the sheet fully on a flat surface to avoid bending or vibration.

If possible, test your cutting method on a scrap piece first.

Using a scoring knife (thin sheets, ≤ 3 mm)

Place a straight ruler firmly along the cut line.

Score along the line with the knife 8–10 times, pressing firmly but steadily.

Slide the sheet so the scored line is right on the edge of your table.

Hold the offcut firmly and press down on the main piece in a quick, even motion to snap along the score.

This method works well for small or medium pieces and is ideal if you don’t have power tools.

Using a saw (thicker sheets)

Use a fine-tooth blade made for plastic/acrylic.

Fully support the acrylic sheet to prevent flexing and vibration.

Feed the material slowly and steadily — forcing it can cause chipping or melting.

Keep the protective film on while cutting to help reduce scratches and edge damage.

This is a good option if you’re making a larger acrylic display case or working with thicker panels.

Using a laser cutter

If you have access to a laser cutter:

Create or export a digital drawing (DXF, SVG, etc.) with all panel shapes and sizes.

Arrange them efficiently on the sheet in the software to reduce waste.

Cut the pieces; the laser will usually leave very clean, precise edges.

Laser cutting gives the most accurate results and is great when you want tight-fitting joints and a very polished look.

After you’ve cut all the panels, keep the protective film on for now. You’ll remove it later, after sanding, edge finishing, and assembly. This small habit makes your acrylic display case box look much cleaner in the end.

Step 2: Prepare the Edges of Your Clear Acrylic Display Case

Before you start assembling your clear acrylic display case, take a little time to clean up all the cut edges. Straight, tidy edges not only look better, they also help the glue spread evenly and reduce bubbles along the seams.

1.Sand the Edges Flat and Smooth

Begin with a medium grit sandpaper, roughly 240–400. Wrap it around a sanding block or a flat scrap of wood so you have a firm, straight surface to work with. This makes it easier to keep the edge sharp and avoids accidentally rounding it off while you sand.

Place the acrylic panel on a solid, flat table or workbench. Hold the sanding block against the edge and move it in one direction along the full length of the panel, keeping the block as close to a 90° angle as you can. Work in long, even strokes rather than rubbing back and forth on one small area, so you don’t create low spots or uneven sections.

Your first goal is to remove saw marks, score lines, and any small chips from cutting. When the edge looks straight and the worst marks are gone, switch to finer grits—typically 600–1000 or higher—to smooth things out. Each finer grit softens the scratches from the previous one and leaves the edge more uniform.

Keep going until the edge feels smooth and consistent when you run a finger along it. For a clear acrylic display case, you don’t need a perfect mirror finish here, but you do want edges that are flat, square, and free of obvious grooves. Clean, accurate edges will give you neater, stronger glue joints in the next step.

2.Optionally Polish the Edges

If you’d like the edges of your clear acrylic display case to look clearer and more “glass-like,” you can polish them after sanding. This step is mainly for appearance—the case will hold together just fine without it.

A simple way is to use an acrylic polishing compound. Put a small amount along the sanded edge and buff it with a soft, clean cloth. With a bit of patience, the cloudy sanding marks fade and the edge starts to look more transparent and glossy.

For those comfortable with tools, flame polishing is another option. Using a small, clean flame such as a propane torch, move the flame quickly and steadily along the edge without stopping in one spot. The brief heat pass slightly melts the surface, helping it smooth out and clear up.

Because too much heat can easily cause bubbles, warping, or scorch marks, always practice on scrap acrylic first. Once you’re confident about the distance and speed, you can use the same technique on the real panels. Just keep in mind: for strong, reliable glue joints, flat and accurate edges are the priority—polishing is a nice visual upgrade, not a structural requirement.

Step 3: Assemble the Acrylic Display Case

Now it’s time to turn those flat panels into a finished acrylic display case. This step is all about accuracy and patience—if you keep everything aligned and don’t rush, the box will look clean and professional.

1.Dry-Fit Everything

Before you open any glue, do a full test fit.

Gently peel back just enough protective film along the edges that will be glued, and leave the rest in place to protect the surfaces from scratches. Then assemble the case without adhesive: lay the base on the table, stand the front, back, and side panels in position, and build the rough shape of the box.

Check every joint carefully:

Do the corners meet neatly?

Does the case sit flat on the table without rocking?

If you notice an edge that’s too long, not straight, or slightly out of square, fix it now by trimming or sanding. It’s far easier to correct mistakes at this stage than after the glue has cured.

2.Set Up a Right-Angle Jig

Crisp 90° corners are one of the biggest differences between a rough box and a tidy acrylic display case.

To help keep everything square, use corner clamps, small boxes, or wood blocks clamped to your work surface as guides. Place the base panel on a flat, stable table, then stand the side panels around it so they rest lightly against these guides.

The idea is simple: once you start gluing, the panels shouldn’t wobble or slide out of position. Your jig holds the shape for you, so you can focus on placing the adhesive neatly instead of constantly adjusting the panels.

3.Apply Acrylic Cement (or Your Chosen Adhesive)

Using acrylic solvent cement (recommended)

For most acrylic display cases, acrylic solvent cement gives strong, clean, and discreet joints.

Position two panels at the correct angle and secure them lightly with clamps or masking tape. Using a syringe or fine applicator bottle, run a thin bead of cement along the inside of the joint. The liquid will be drawn into the seam by capillary action and begin to fuse the edges together.

Hold the panels steady for about 30–60 seconds until the joint can support itself. Let that joint sit for a few minutes before moving on. A simple assembly order that works well is:

Glue the front panel to the base.

Glue one side panel to the base and front.

Glue the second side panel.

Glue the back panel.

Glue the top panel last, if your design has a fixed lid.

Building in this sequence helps the case stay square as you go.

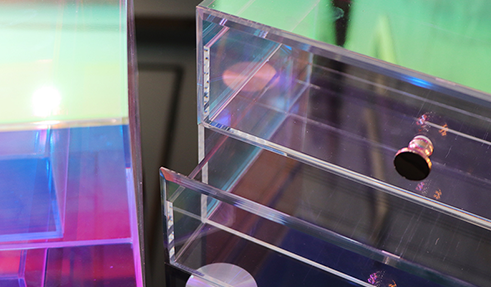

Using screws and brackets (mechanical method)

If you want a case that can be taken apart or adjusted later, you can use screws and corner brackets instead of solvent cement.

First, pre-drill small holes near the edges with a drill bit designed for plastic, going slowly and using light pressure to avoid cracking. Then use small screws and metal or plastic brackets to pull the panels together at each corner. Tighten just until snug—over-tightening can stress or fracture the acrylic.

This method is useful for modular designs or projects you may want to modify in the future.

Using epoxy (alternative adhesive)

Epoxy is another option if you don’t have acrylic cement.

Mix the epoxy according to the manufacturer’s instructions. Apply a thin, even layer to the edges that need to be joined, bring the panels together, and hold them in place with clamps or masking tape. Wipe away any excess epoxy that squeezes out along the seam before it starts to harden.

Epoxy usually cures more slowly and leaves a more visible glue line, but with careful application it can still produce a strong, practical acrylic display case.

4.Let It Cure

Once all the panels are glued or fastened, give the acrylic cases for display time to fully set.

Even if the joints feel firm after a few minutes, they’re not at full strength yet. Avoid lifting the case by the walls, pressing on the corners, or placing anything heavy on top for at least several hours. Always check the curing time recommended on your cement or epoxy, but as a general rule, a full cure often takes around 24 hours or more.

Place the acrylic display case on a flat, safe surface while it cures, and try not to move it. Letting it sit undisturbed at this stage will give you cleaner seams, stronger joints, and a sturdier display that holds up better over time.

Step 4: Finishing Touches for Your Acrylic Cases for Display

This is the stage where your project stops looking like a rough DIY box and finally turns into a clean, display-ready acrylic display case.

1.Check and Seal Gaps (If Needed)

Under good lighting, carefully inspect every joint of your acrylic cases for display.

If you spot small gaps, you can run a thin line of acrylic cement along the seam a second time. The solvent may soften the edges just enough for the joint to tighten up. For a simple dust-cover style case that sits over a base, tiny gaps are usually fine as long as dust can’t easily get in.

Fix the gaps that you notice at a glance, but avoid going over the same area too many times—you don’t want to melt, mark, or distort the panels.

2.Clean the Surfaces

Next, remove any remaining protective film from the acrylic.

Peel the film slowly to reduce static, then clean the panels with mild soapy water or an acrylic-safe cleaner. Use a soft microfiber cloth and wipe in light, straight strokes rather than scrubbing hard.

Avoid ammonia-based glass cleaners and rough cloths or paper towels, as they can scratch or cloud the surface. A quick, gentle clean here will make your acrylic cases for display look clear, bright, and ready to use.

3.Add Protective Pads or Feet

To protect your furniture and give the base a more finished feel, stick small rubber feet or felt pads under the bottom of the case. This helps prevent scratches and adds a bit of grip so the case doesn’t slide around.

If your clear cover drops over a separate base, you can also add thin silicone strips or foam tape where the two parts meet. That reduces slipping, softens the contact, and helps prevent squeaks when you lift the cover on and off. These small details make the acrylic display case more comfortable to handle every day.

4.Optional Enhancements

If you’d like to personalize your acrylic display case, a few simple upgrades can make a big difference:

Add a background panel using colored paper, vinyl, or thin wood to make the items inside stand out.

Install subtle LED strip lights along the base or top, making sure they stay cool and don’t overheat the acrylic.

Attach a small nameplate or label for a clean, museum-style presentation.

Use an inner stand or riser to lift one item higher and create a more layered, interesting layout.

Even just one or two of these touches can make your acrylic cases for display feel truly custom-made for your collection.

Conclusion

Building an acrylic display case takes a bit of measuring, patience, and careful handling, but the result is a custom piece that fits your collection far better than a generic store-bought box.By planning the dimensions, preparing clean edges, taking your time with assembly, and adding a few finishing touches, you end up with a clear, sturdy display that really shows off what’s inside.

Table of Contents