Acrylic Processing Technology

November 18, 2025

Read:9

Source: Dongguan XingfenglinAcrylic Products Co., Ltd

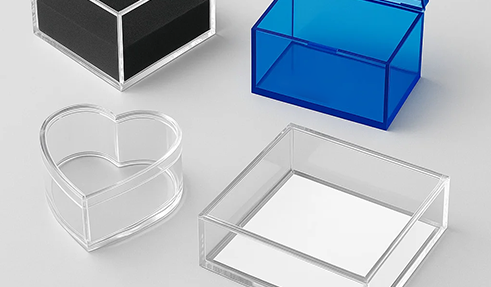

Acrylic, chemically known as polymethyl methacrylate (PMMA), is commonly called plexiglass. It is widely used in advertising, architectural decoration, and mechanical parts due to its high transparency, good processing performance, and rich color selection. Acrylic sheets, as a common processing material, are commonly shaped using processes including laser cutting, engraving, bending, polishing, bonding, printing, and CNC machining.

At the initial product design stage, designers need to consider subsequent processing steps, sheet thickness, dimensions, and the points to note for each processing step when selecting materials to reduce the time and cost of subsequent prototyping.

1. Cutting

Laser Cutting

High precision, fast cutting speed, smooth cut, no need for subsequent grinding, easily achieves complex shape cutting, and ensures high consistency for mass production.

Notes: The acrylic sheet film needs to have high adhesion. It is necessary to communicate in advance when purchasing the sheet to prevent the sheet from being scratched by cutting powder. Excessive sheet thickness will increase processing difficulty.

Engraving & Cutting

High precision, better suited for complex shapes, producing fine results. Points to note: High processing difficulty; avoid cracking the acrylic sheet, surface burns, or unclear engraving when using a rotating cutter head.

Saw Cutting

Relatively inexpensive, with some cutting error; suitable for cutting large sheets into smaller sheets for transportation.

2. Printing

Printing patterns and text onto acrylic sheets enhances their decorative and functional qualities, widely used in electronic panels, advertising, and product labeling. Common methods include screen printing and UV printing. Single-color screen printing is simple to operate and low-cost; UV printing cures quickly and provides good image durability.

Points to note: The acrylic surface must be cleaned before printing. If the acrylic surface has undergone hardening/wear-resistant treatment, the water droplet angle parameters may change, potentially affecting ink adhesion. An ink/electroplating adhesion test is necessary. (Currently, the electronics industry uses advanced printing methods, employing two-component strong adhesion inks to balance adhesion and surface hardness.)

3. Drilling

Acrylic can be directly drilled using a drilling machine. Compared to glass, acrylic has excellent machinability. Simply place the acrylic on the drilling machine according to the processing drawings and fix it in place for drilling.

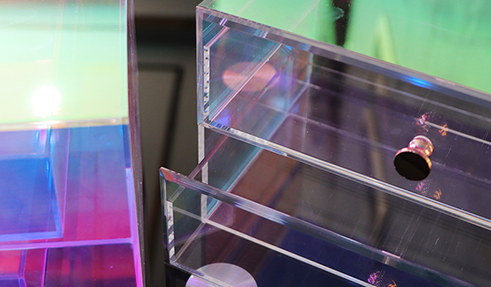

Acrylic can also be CNC drilled. This produces acrylic parts with very high assembly precision. We only need to input the various parameters from the drawings into the computer, and then use the computer to control the CNC machine for positioning and drilling.

4. Polishing

Acrylic itself has high transparency, comparable to naturally occurring crystal. Therefore, we need to polish it to restore its crystal-like transparency. Acrylic polishing can use traditional cloth wheel polishing, diamond polishing, or fire polishing.

The general order of processes is as follows: After diamond polishing, flame polishing is used to remove burrs from the edges and corners, making the acrylic product smooth. Then, cloth wheel polishing is used. After applying wax to the cloth wheel, acrylic products with a transparency of over 92% can be polished.

5. Hot Bending

Because acrylic softens at 70° to 100°, hot bending technology allows acrylic to be processed into various shapes and irregular parts as needed. Acrylic hot bending can be achieved in different ways. Multiple acrylic sheets can be placed on a hot bending machine and shaping mold for simultaneous hot bending and shaping. Most hot bending is done along a single line or parallel lines. The bending angle can be controlled by the mold as needed.

6. Bonding

Bonding Surface: Before bonding, ensure the bonding surfaces are clean, dry, and free of dust and other impurities. Note that acrylic sheets with surface hardening treatment may have an overly smooth surface, affecting the bonding effect. In this case, the hardened coating can be scraped off before bonding.

Adhesive: Select a suitable adhesive based on the acrylic thickness and the intended use environment. In addition to general-purpose acrylic adhesives, outdoor-specific adhesives with good weather resistance should be chosen for outdoor acrylic products. Sufficient time is required for acrylic bonding; for large structures like acrylic aquariums, complete curing may take several days.

7. Assembly

Assembly involves assembling the various processed acrylic components to create a complete product. At this stage, a quality inspection of the entire product is necessary to ensure everything is in order before packaging and shipping.

Table of Contents